Instructions for Filling Ds10 Disposable

Start by filling a small test batch of about 200 units to test functionality before proceeding with larger batches.

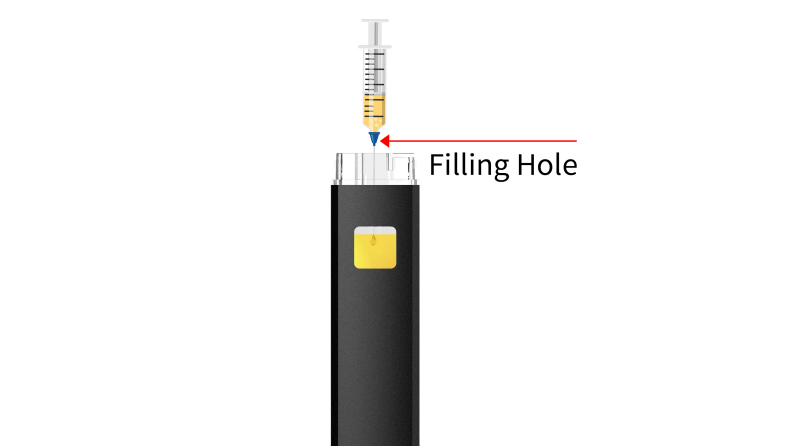

Fill the oil into the middle hole; avoid filling the side hole as it serves as the airpath. Filling the side hole can cause clogging and leaking.

Aim to fill the oil at a temperature below 120°F. If the oil temperature exceeds this, consider turning the cartridge upside down after filling until the oil reaches room temperature.

Note the minor temperature variations required for different products, such as distillates and live resins. Live resin typically operates at lower temperatures, making it a bit more challenging to handle through the filling process compared to distillates. These differences can affect viscosity and ease of filling.

Cap the device within 1 minute of filling to prevent leakage. Please pay attention to the square silicone seal in the center of the mouthpiece. If the silicone seal is loose or slightly lifted, ensure the silicone is flat before pressing down on the mouthpiece cover. After filling, check for leaks by placing the device upside down.

Avoid overfilling the cartridge; aim to fill a maximum of 1ml, as overfilling might push oil into the airpath, potentially causing clogs or damaging the cartridge. Most of our customers prefer filling 0.8ml into the device instead of 1ml.

When installing the mouthpiece, avoid pressing or twisting too hard.

Use short needles when filling, ensuring they don’t touch the bottom of the oil tank to prevent damage to the ceramics or excessive heating.

Understanding the nuances between different oil products, especially in terms of temperature variations, can greatly impact the filling process. These differences in viscosity and handling could influence the ease of filling and should be considered when working with various oil types.